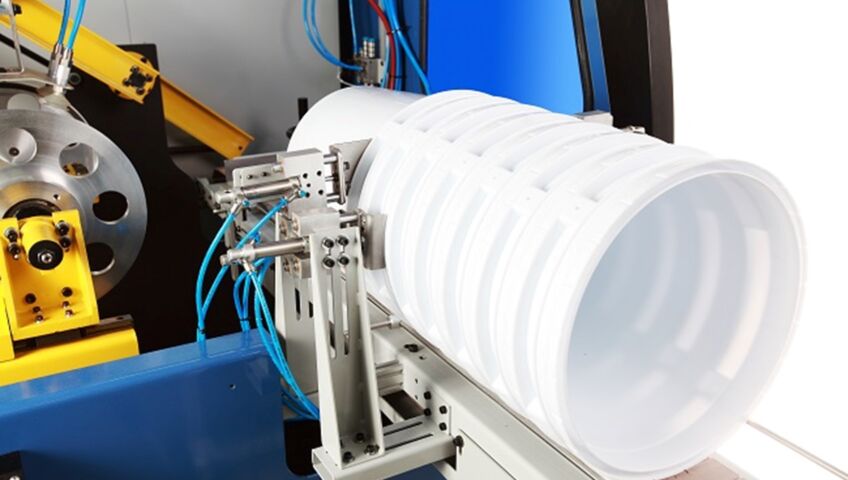

Molds play a decisive role in determining the quality of plastic buckets. Taking a 20L mold as an example, in China, a standard mold is typically priced around $30,000 USD. The material used is usually 45# steel (considered the lowest grade, with special treatment during mold opening to increase its hardness) or P20. Molds are divided into moving and fixed parts, or front and rear parts, with each part further divided into mold frames and mold cores. Often, mold factories use better-quality material for the mold core and slightly inferior material for the mold frame, as the mold core is directly involved in product formation. The injection cycle for a 20L bucket mold is generally around 40 seconds with a standard injection molding machine. Similarly, the quality and price of P20 steel vary among manufacturers, with Baosteel being the best but also the most expensive, significantly differing from the prices of smaller factories.

Read more